Description

Product Description

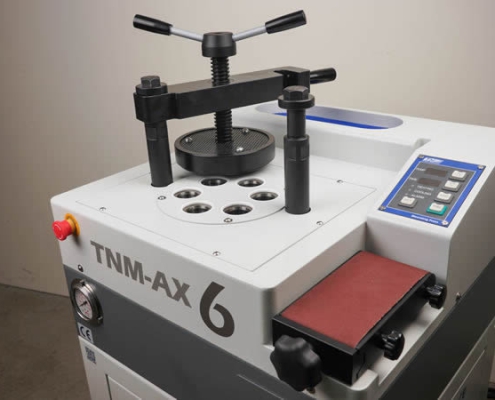

Hot Mounting Press Machine is used to encapsulate metallographic specimens in a resin under high temperature and pressure. This process creates a solid, easy-to-handle sample for grinding, polishing, and microscopic analysis. It ensures edge retention and protects delicate structures, making it ideal for labs, quality control, and research applications.

Efficiency Prerequisite

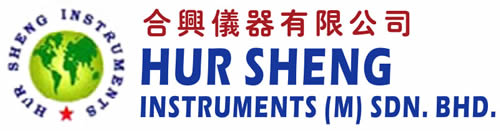

Multi-mode Embedded Automatic Hot Mounting Press Machine is a powerful hot mounting machine that can compelete 6 molding samples at the same time. For one process, it takes about only 15 minutes for 6 samples to produce.

Multi-mode Concept

After you completed the molding process, the multi-mode embedded technology allow you to directly proceed with rough grinding operation to fasten your sample preparation operation process.

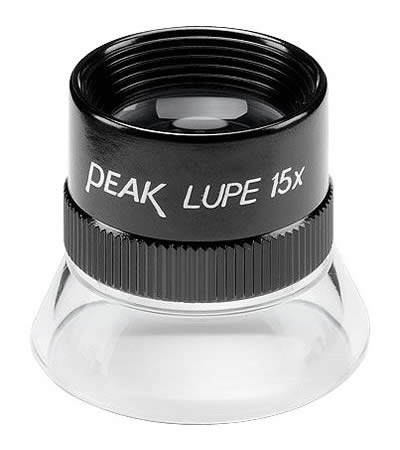

Useful and Ergonomical Design

The machine is design to make your job easier. Every part of the design was made very thoughtful to increase productivity and efficiency.

Specifications

| Item | TNM-AX6 | |

| Mounting Parameters | Size | Ø32mm |

| Greatest Pressure | Inside the mold tube:1625psi(114kgf/cm^2);actuation pressure:130kgf/cm^2 | |

| Pressure Control System | Uncontrollable, hydraulic system | |

| Filling Mechanism | Rotary push down | |

| Quantity | 1-6(single MAX high:30mm | |

| Temperature | 110ºC – 200ºC | |

| Panel Function | Production Mode | Full automatic pressure compensation |

| Function Setting | 1. Forming time 2. Cooling time 3. Forming temperature |

|

| Extra Features | 1. Automatic shutdown 2. Buzzer mode selection A. On B. Off C. Buzzer for 30 seconds |

|

| Security Mechanism | Safe Temperature Protection | The system cannot operate until the safe temperature is reached |

| Emergency Safety Switch | After the emergency switch is pressed, all functions stop | |

| Overload Protection | The machine has a complete overload protection mechanism | |

| Supply | Electricity | Three phase 220V/ 380V 60/50Hz |

| Heating Power | 3000W | |

| Total Machine Power | 3500W | |

| Size | W540 x D552 x H1300mm | |

| Weight | 120kg | |

| Cooling Water | Inlet pipe size 3/8″ inch (3 pipes) | |

| Outlet size 5/8″ inch (5 pipes) | ||

| Standard Equipment | Dispensing scoop x 1; funnel x 1; water inlet pipe 2M x 1; drain pipe 2M x 1; release agent x 1; #240 abrasive paper 4 sheets; grinding belt table x 1; Hot gloves x 2; upper mold scraper x 1 | |